Extruders play a crucial role in various manufacturing industries, offering a versatile solution for processing and shaping materials. These machines are designed to push or pull a material through a shaped opening, creating a continuous form with a consistent cross-section. Industries such as plastics, food processing, pharmaceuticals, and construction rely heavily on extruders to produce products ranging from plastic pipes to food products like pasta.

Types of Extruders

Overview of Different Types of Extruders

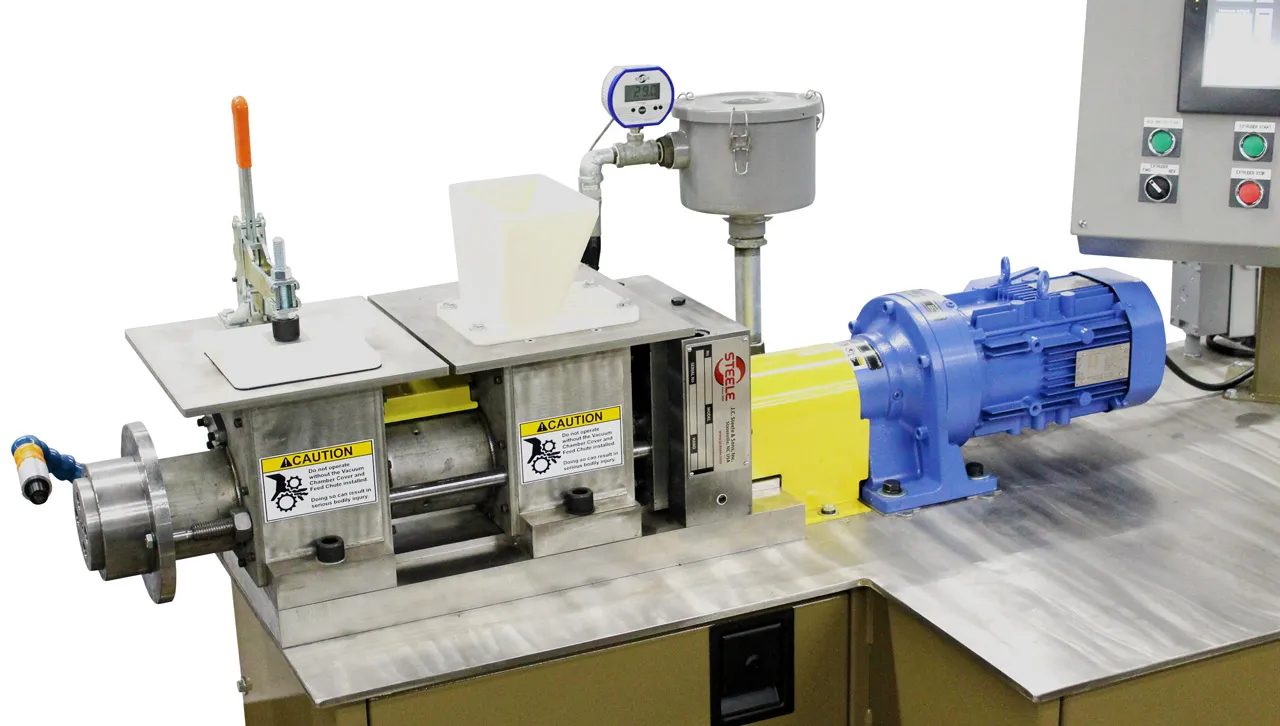

Extruders come in several types, each tailored to specific manufacturing needs. Single-screw extruders are the most common, suitable for processing a wide range of materials such as plastics, rubber, and food products. Twin-screw extruders offer enhanced mixing capabilities, ideal for compounding and reactive extrusion processes. Similarly, ram extruders are used for ceramics and metals, while hot melt extruders are crucial in pharmaceuticals for creating solid dosage forms.

Applications and Benefits of Each Type

Each type of extruder offers unique advantages. Single-screw extruders are cost-effective and versatile, making them suitable for general-purpose applications. Twin-screw extruders excel in complex mixing tasks and can handle materials with varying viscosities and properties. Ram extruders provide high-pressure capabilities, essential for dense materials like ceramics. Hot melt extruders ensure precise temperature control, critical in pharmaceutical formulations to maintain product integrity.

Factors to Consider When Buying an Extruder

Selecting the right extruder requires Extruders for sale careful consideration of several factors to ensure optimal performance and cost-effectiveness.

Key Considerations for Selection

Capacity is a fundamental factor, determining the output volume and size of materials the extruder can process. Material compatibility involves assessing whether the extruder can handle the specific properties of the material, such as viscosity and temperature sensitivity. Operational requirements, including energy consumption, maintenance needs, and production speed, impact overall efficiency and operational costs.

Customization Options and Additional Features

Some extruders offer customization options such as interchangeable screws or barrels, allowing flexibility in processing different materials. Advanced features like touchscreen interfaces for precise control, automatic feeding systems, and safety enhancements improve user experience and production reliability.

Top Manufacturers and Suppliers

The market for extruders is diverse, with several reputable manufacturers and suppliers offering a range of products tailored to industry needs.

Reputable Manufacturers

Leading manufacturers include names like Coperion, Bühler, and Davis-Standard, known for their innovation and reliability in extrusion technology. Each company specializes in different types of extruders, catering to various industrial applications from plastics to food processing.

Supplier Profiles and Specialties

Suppliers such as Alibaba and ThomasNet connect buyers with a wide network of manufacturers, offering competitive pricing and comprehensive product listings. Their platforms facilitate easy comparison of features and pricing, ensuring buyers find the right extruder to meet their specific requirements.

Cost Analysis and Budgeting

Investing in an extruder involves considering both initial purchase costs and long-term operational expenses.

Typical Cost Range

Extruder prices vary significantly based on type, size, and manufacturer. Single-screw extruders start at around $20,000 for smaller models, with larger, specialized units costing upwards of $100,000. Twin-screw extruders generally range from $50,000 to over $500,000, depending on capacity and features.

Factors Influencing Pricing

Factors influencing pricing include extruder type, material of construction (such as stainless steel for food-grade applications), automation level, and additional features like cooling systems or inline monitoring devices. Customization and special requirements may also impact overall costs.

Where to Find Extruders for Sale

Navigating the market for extruders involves exploring various channels and platforms to ensure quality and reliability.

Online Marketplaces and Industrial Platforms

Platforms like Alibaba, eBay, and industrial equipment websites offer extensive listings of new and used extruders. These platforms provide detailed product descriptions, seller ratings, and customer reviews, aiding in informed decision-making.

Verification of Seller Credibility

Ensuring seller credibility is crucial to avoiding fraudulent transactions and ensuring product quality. Verified sellers and platforms with buyer protection policies offer peace of mind, guaranteeing that extruders meet expected standards and specifications.

Case Studies or Examples

Real-world examples illustrate the practical benefits and applications of extruders across different industries.

Successful Implementations

Companies like Nestlé and Dow Chemicals showcase successful implementations of extruders in food processing and plastics manufacturing, respectively. These case studies highlight efficiency improvements, product quality enhancements, and cost savings achieved through strategic extruder use.

Conclusion:

Extruders are indispensable in modern manufacturing, offering versatility, efficiency, and precise control in material processing. Choosing the right extruder involves considering specific application needs, operational requirements, and budget constraints to maximize return on investment and ensure seamless production processes.