Stainless casting is a crucial process used across various industries, from automotive to aerospace. It involves pouring molten stainless steel into molds to create intricate shapes and parts. The quality of these castings can significantly impact the performance and durability of the final products. Therefore, selecting the right manufacturer is essential. A reliable stainless casting solutions manufacturer not only ensures high-quality output but also adheres to industry standards. In this guide, we will explore what stainless casting is, the key factors to consider when choosing a manufacturer, and the benefits of collaborating with a professional in the field.

What is Stainless Casting?

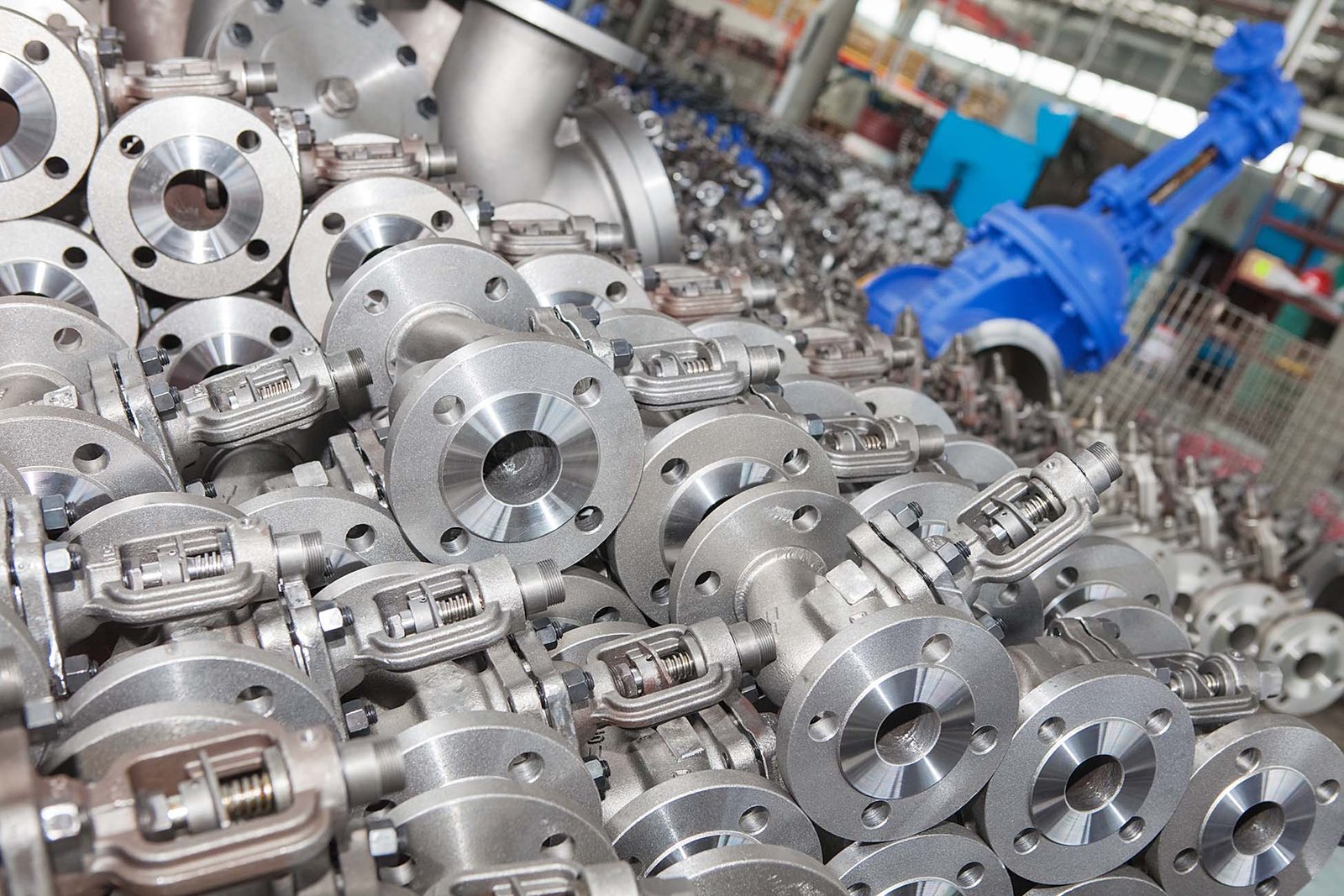

Stainless casting refers to the process of shaping stainless steel into specific forms through casting techniques. This involves melting the steel at high temperatures and pouring it into molds, where it solidifies into the desired shape. Stainless castings are popular due to their excellent resistance to corrosion and high temperatures, making them ideal for harsh environments. Common applications include parts for machinery, valves, and industrial equipment. The versatility of stainless casting allows for both small-scale and large-scale production, accommodating various industries. Understanding this process is vital for anyone looking to procure stainless steel components, as it highlights the importance of quality and precision in manufacturing.

Key Factors to Consider When Choosing a Manufacturer

When selecting a stainless casting solutions manufacturer, several key factors come into play. First and foremost, consider the manufacturer’s experience and expertise in the industry. A company with years of experience is likely to have refined its processes and developed a strong reputation. Additionally, quality assurance practices are essential. Look for manufacturers that implement strict quality control measures to ensure the durability and reliability of their products. Furthermore, consider the range of products offered. A manufacturer that provides a variety of stainless castings can cater to diverse needs, making it easier for you to find the right components for your projects.

Benefits of Working with a Stainless Casting Solutions Manufacturer

Collaborating with a reputable Stainless Casting Solutions Manufacturer offers several advantages. One significant benefit is customization. Many manufacturers can tailor their castings to meet specific project requirements, allowing for unique designs and specifications. This flexibility can lead to better-fitting parts and improved overall performance. Additionally, working with an established manufacturer can be cost-effective. They often have optimized processes that reduce waste and enhance productivity, which can translate to lower costs for customers. Timely delivery is another critical factor; a reliable manufacturer will ensure that your orders arrive on schedule, helping you maintain project timelines and avoid delays.

Understanding the Manufacturing Process

The manufacturing process of stainless casting involves several steps, each critical to producing high-quality components. It begins with creating a mold, which can be made from various materials depending on the casting method used. Once the mold is prepared, stainless steel is melted in a furnace and then poured into the mold. After cooling and solidification, the casting is removed from the mold and undergoes finishing processes like machining and polishing. Advanced technologies, such as 3D printing and computer-aided design (CAD), are increasingly used to enhance precision and efficiency in this process. Understanding these steps can help buyers appreciate the intricacies involved in producing stainless castings.

Quality Standards in Stainless Casting

Quality standards play a crucial role in stainless casting, ensuring that products meet specific performance criteria. Manufacturers often pursue certifications like ISO 9001, which demonstrates a commitment to quality management systems. Adhering to industry standards is essential for maintaining consistency and reliability in production. Testing and inspection are integral parts of the quality assurance process. This includes examining the mechanical properties of the castings, as well as conducting non-destructive testing to identify any internal flaws. By prioritizing quality standards, manufacturers can guarantee that their products are not only safe but also effective for their intended applications.

Case Studies: Successful Collaborations

Examining case studies of successful collaborations can provide valuable insights into the benefits of working with a stainless casting solutions manufacturer. For instance, an automotive company may partner with a manufacturer to create custom components for a new vehicle model. This collaboration could lead to innovative designs that enhance performance and efficiency. Similarly, a medical device company may require stainless castings for critical components that need to meet strict regulatory standards. In these cases, the right manufacturer can make a significant difference in the project’s success, ensuring that the castings meet both design and quality requirements. Such examples highlight the importance of choosing a manufacturer with a proven track record in your specific industry.

Frequently Asked Questions

When it comes to stainless casting, potential buyers often have several questions. Common inquiries include how to determine the right manufacturer, what materials are used in casting, and the typical lead times for production. It’s essential to research and compare different manufacturers to find one that aligns with your needs. Additionally, understanding the types of stainless steel used in casting, such as 304 or 316 grades, can impact the performance of your final products. New customers should also inquire about minimum order quantities and customization options, ensuring they receive the best value for their investment.

Conclusion

Choosing the right stainless casting solutions manufacturer is vital for ensuring quality and reliability in your projects. By considering factors such as experience, quality assurance practices, and customization options, you can make informed decisions that align with your needs. Remember, the success of your project depends on the quality of the components used, making thorough research and evaluation essential.